DRIJET CASE STUDIES

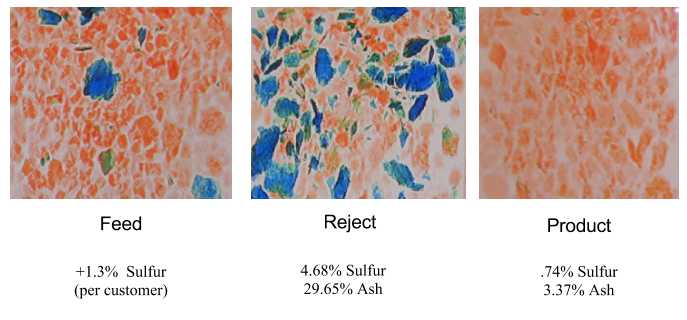

Blue Creek - Alabama

This customer had a met coal with a sulfur problem. When his sulfur was less than 1%, he could sell his coal as met, but when the sulfur was higher than that he got a much lower price. Lately, his sulfur percentage had been creeping up. Because the price difference between met and non-met was so extreme, it was appropriate to configure the DriJet to be extremely aggressive on pyrite, even at the price of coal loss in the reject.

DriJet brought the coal back to met quality. And because the coal was soft, most of the "lost" coal in the reject could be recovered by screening.

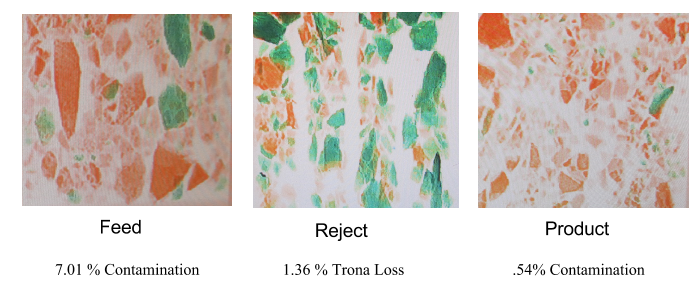

Trona - Wyoming

This customer has a trona (sodium bicarbonate) mine. The quality of the mined trona was decreasing. Contaminant levels had become too high. DriJet needed to remove the contaminants without losing trona.

DriJet gave an excellent result. It effectively reduced the contaminant without losing trona.

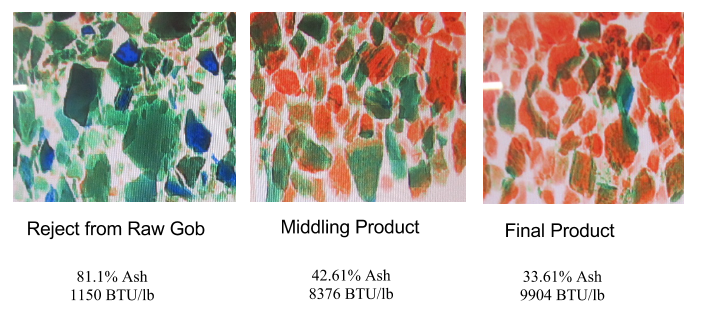

Gob - Western Arkansas

This customer has a gob pile of many millions of tons. Recoverability is poor, with 78.2% ash and 1844 BTU/lb. We ran the DriJet in a two-pass configuration. On the first pass we configured the DriJet to eject the coal from the gob. This created a middling product. On the second pass we configured the DriJet to eject the ash from the middling.

DriJet gave an excellent result. It extracted a salable product from a gob pile of low recoverability.

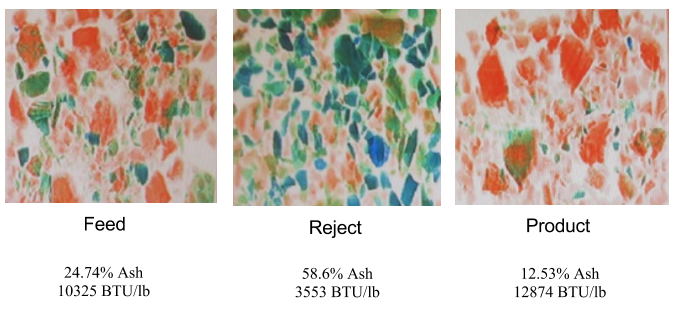

P8 - Greene County, PA

This customer has a reserve of over 10,000,000 recoverable tons of P8 and was interested in improving it.The goal was to remove rock with high throughput from a 2" X 0 feed at the mine face. Fine coal would be recovered from the reject via screening. We ran his sample through the DriJet running a destoning configuration.

DriJet gave an excellent result. The ash in the product stream dropped in half. Most of the coal in the reject fraction tended to be fine in size and was easily recovered with a screen.